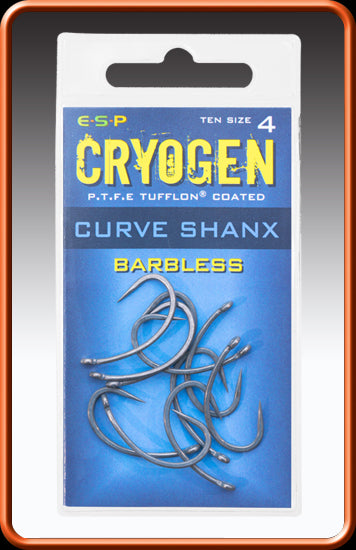

ESP Cryogen Curve Shank Hooks

Product Description:

The ESP Cryogen Curve Shank Hooks are engineered for serious carp anglers who demand unmatched strength, sharpness, and hooking efficiency. Manufactured using ESP’s exclusive Cryogen tempering process, these hooks are 25% stronger than standard hooks while retaining their razor-sharp, needle-like points for exceptional penetration.

The aggressive curve shank design ensures the hook turns quickly and securely, making it ideal for popular rigs such as the Ronnie, blowback, and D-rigs. Finished with a low-glare PTFE coating, these hooks offer maximum stealth and a natural presentation to fool even the wariest carp.

Whether you’re fishing over hard gravel, silt, or weed, the ESP Cryogen Curve Shank Hooks provide total confidence with every take.

Key Features:

-

Cryogen tempering process – 25% stronger and longer-lasting

-

Aggressive curve shank for fast rotation and solid hook holds

-

Perfect for Ronnie rigs, D-rigs, and blowback rigs

-

Low-glare PTFE coating for ultimate underwater concealment

-

Needle-sharp points for reliable penetration

-

Available in barbed and barbless versions

-

Supplied in packs of 10 hooks